BayMotor Products

Sunday 17 September 2017

Electric Motor Work

Magnetism and movement was discovered by the French physicist Andre-Marie Ampere in 1820 - that is the fundamental science supporting an electric motor's operation. To describe this, we'll need to point out wires in an electric chainsaw.If we were to bend the cable into a U-shaped loop to operate more efficiently, the parallel wires would make a magnetic field. The electrical current is taken by among those cables away from stage A and another one could bring the back that is present. This is due to the fact that currents flow in opposite directions.

One of those cables in the circuit will proceed when we turn on electricity in a system and the wire will move. If the coil of wire proceeds to proceed in this fashion, it take form and would rotate continuously.There are two ways whereby this issue can be overcome by an electric motor. One method is to utilize an electric current that reverses direction periodically, also known as an alternating current. The other would be to use a part and add this component. It is often discovered that the latter solution is the solution.

The connection between the theories of power, motion and magnetism was discovered by the French physicist Andre-Marie Ampere in 1820 - this is the basic science supporting the operation of an electric motor. To explain this, we will need to point out cables in an electric motor shell.A simple engine with fundamental components isn't capable of making large quantities of electricity; therefore, it's possible to increase the torque or turning force of the motor. This increase can be conducted by either using a more powerful magnet, by increasing the electric current flowing through the wire, or by designing the coil so it has turns from the thin wire.

Ideally, a straight magnet with thin, straight cables will not have higher torque compared to a heavy duty magnet that's circular in shape. The fundamental idea behind any electrical motor would be to merely flick a switch and get immediate power. In all types of appliances, the use of electricity at one's fingertips is appealing and would have been exciting to our ancestors. Despite the prevalence of electric motors in the society of today, not men and women consider how they operate.

We utilize power regularly, but only a few of us sit back to ponder the way the power works for us. This article will examine this matter and provides information about how electric motors work. The usage of a commutator entails the shifting back and forth of a current on the cable coils. The part itself presents as a metal ring that separates the two parts of the motor and reverses the current from the coil every time a coil rotates. 1 end of the coil is attached to the commutator and the electric current is routed from the battery terminals in the motor. The terminals feed power to power and the commutator is flowed through the circuit.

5 Frequent Uses of Electric Motors

The subsequent five distinct everyday uses of electrical motors can surprise you. Some of them are going to be something you may have on you at any given moment and others might run in the background without anyone giving them much consideration.

- Mobile phones -

Did you realize that a electric motor is ? It isn't important if you using it as an alarm or are currently obtaining a telephone clock, you can thank the small electric motor that is that it provides. This engine operates without many of us giving any thought to it, but it has made our lives more convenient. As you can see, using electric motors is ingrained into society. Though we may never stop and think about their applications we do take advantage of what they must offer regularly.

- Inside our Vehicles -

There are multiple electric motors operating at any time inside of our vehicles, and we don't even realize it. Some of those motors may keep us comfortable by controlling the air flow and temperature of the car interior. Electric motors are used for closing and opening the windows and even working the windshield wipers.

- Refrigerators -

A common use of electrical motors in the house is the refrigerator. Again, the door only open and recover something cold without given much consideration to what is behind it from the inside. Electric motors are employed to pump refrigerant gas. This helps to keep the drinks and food inside of the refrigerator secure and at a temperature that is suitable and forces cold air to circulate.

- Water Supply -

Once you get in the shower and turn the knobs, you get tidy and may anticipate that water arrives and we go. The fact of the matter is electric motors are in use in the backdrop that helps to power what's essential to push against the water in your home. These electric motors are the pumps which supply your residence with the water. It not only gets the water from the water station but it also provides the water pressure that you take advantage of on a day-to-day basis.

Electric motors are frequently used within a commercial environment and globally, they are responsible for the majority of energy use. Although most people think about big motors that are employed in this manner, there are also some ways that motors are utilized on a day-to-day basis too. These typical uses for electric motors aren't often considered, but it can make a difference on your view of the item that was common as soon as you know them.

- Electric Vehicles -

More and more frequently vehicles are being used around the road. If we do not have one at our disposal nonetheless, we could thank the usage of these electric vehicular motors for additional fuel that is available and cleaner air for our use.

Saturday 16 September 2017

3 Things You Need to Know About the Various Types of Appliances

Hopefully, the following 3 examples of everyday appliances with mill motors provide you a better idea of exactly how ordinary blowers have been in modern appliances. These elements make it possible for devices to perform a few distinct jobs.

- Furnaces: The way that a heater works is relatively simple. When the furnace kicks on, there is a heating source triggered. This heat source can either be powered by gasoline or electricity, based on which type of furnace it is.

- Refrigerators: Refrigerators rely upon a collection of components to keep your food cold. These parts include a compressor or condenser unit, evaporator coils, condenser coils, refrigerant and an expansion device. Through the process of evaporation and moisture, these pieces are capable of preventing your food and keeping the interior of the refrigerator cold.

- Range hoods: Range hoods to a great job of managing everything from airborne contaminants particles and smoke to steam and heat. Removing these contaminants can prevent dirt, soot, or moisture from building up on surfaces at the place and can help improve indoor air quality. One frequent sort of component that lots of appliances contain is a blower engine.

Here are three examples of everyday appliances with blowers:

When the atmosphere is heated, a blower motor activates and starts turning a powerful fan.

This fan blows the hot air out to the ductwork, sending it out so that it could be delivered to the rooms of the house.

The air that is heated finds its way to the ground or wall vents, allowing it to heat areas of the home that are located far away from the furnace.

Through the years, technology has led to significant inventions that have completely changed the way that we live. Standard appliances are responsible for everything from creating household chores easier to simplify the procedure for preparing and storing food. Of course, those machines are only useful when they are currently working. They rely on a succession of parts which are all connected to one another. The condenser unit is among the most vital parts of this process. It has a fan that draws in air from the room.

This air passes as it goes by absorbing heat. The breaker is also passed back by by it and then is blown back out to the space. This method is based Range hoods. When you cook foods grease, smoke, and other contaminants are released into the atmosphere. Range hoods are mounted over the cooking surface and are intended to remove these contaminants from the atmosphere. They operate

with a blower motor to activate a buff which blows off on the air from the room.

Friday 15 September 2017

Picking the Proper AC Motor

Both AC and DC motors may use a similar principle of this Armature winding along with the magnetic field that is available. With a DC motor is a gap in the spinning. The Armature will rotate at a DC motor, but the magnetic field is not currently going to vibrate. Having an AC motor, the reverse is true. The Armature will not rotate, although you will see a continuous rotation together with the field. AC motors can be found in a single stage, or they might be three phase.The primary distinction between an AC motor and a DC motor is the type of current that's supplied to the motor itself.

DC electric motors use Direct Current (DC) whereas AC motors use an Alternating Current (AC). There are some significant differences between both of these different types of motors which can make among them more convenient for your use. There are always going to be choices in regards to choosing a engine to make sure that you can find the work done properly. Those choices might include the size of the horse electricity the engine and any energy efficiency options which may be available. Another difference that might be thought about is if you're going to use an AC motor or a DC motorvehicle.

Difference between both of these types:

These days, it is possible to adjust speed and the torque of an AC motor externally by using a variable frequency drive . These drives can conserve money and power, and a AC engine can be used by you oftentimes. There are also ways to avoid the issue although they do have some drawbacks. You also need to consider the use of the engine when it comes to Picking between AC or DC. Normally, if it is vital to control the motor speed externally, the DC motor is going to be the best alternative.

It is possible to control a DC motor simply by increasing or decreasing the power. AC motors, on the other hand, are best when it is necessary to experience electricity on a constant basis over a long duration. Occasionally, it's just necessary to choose the one which is most cost-effective since there are choices to substitute one with the other. This is something that should be considered carefully because your business depends on it.

Tuesday 21 June 2016

Preparing for Your Scheduled Shutdown? 7 Things to Check

Facility equipment - especially industrial motors - naturally wear down throughout operation, sometimes to the point of failure. In order to avoid costly unplanned downtime, plant managers should administer scheduled shutdowns at least once a year. Annual motor maintenance not only lengthens equipment life - it also decreases energy consumption. These planned shutdowns allow for […]

The post Preparing for Your Scheduled Shutdown? 7 Things to Check appeared first on Renown Electric.

Friday 25 March 2016

Configure online a Servo Motor, Gearbox and Encoder. Ships in 11 Days !

Configure and combine any DC servo motor (DCX, DC-max), gearbox (GPX) and encoder (ENX) according to your individual customized requirements using Maxon’s online platform.

The configured drive systems are built in 11 working days and ship directly from Switzerland to your location.

Detailed product data can be viewed online immediately and 3D data for the configuration is available for immediate download.

Tags: maxon, DCX, Electromate, brush motor, dc brushed motor, dc motor, gear, gearhead, gearheads, motion control, motors, motors & motion control, electric motor, encoder, GPX, ENX, DC-max

Updated FAQs Page

Groschopp’s updated FAQs page addresses many common questions about our company and what we do, purchasing new motors or getting replacement parts, and technical questions about product details. Our full list of questions can be found on Groschopp’s FAQs page. If you have any additional questions, please contact our sales team and they would be happy to help.

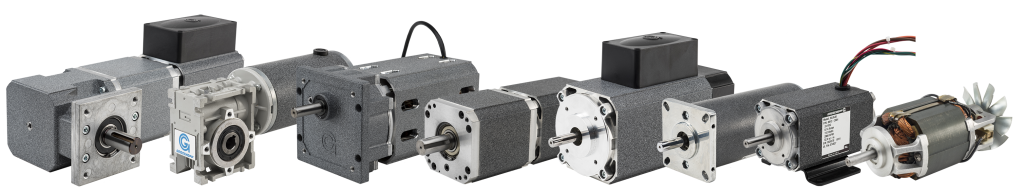

What types of motor does Groschopp sell?

We manufacture a full line of fractional horsepower PMDC, AC Induction, Brushless DC and Universal motors and a full line of Parallel Shaft, Planetary, Right Angle Worm and Right Angle Planetary gearboxes. Each of these combinations can be modified or custom built to make sure you are matched with the best motor or gearmotor to fit your specific needs.

What do lead times look like?

Our Fast Track department can build and ship standard or modified motors in 48 hours. This typically includes orders under 25 pieces. Larger orders will run through production, and lead times for these will vary based on factors such as quantity or special material requirements.

The specs I need aren’t listed, does Groschopp offer other motors?

The products listed on our website are only a fraction of the motors and gearmotors we offer. Our proprietary software, MOTORTEC™, allows us to search thousands of standard combinations in just seconds. If you don’t see the specific motor you need, give us a call at 800-829-4135, and we will work with you to determine the right match for your application.